Machining

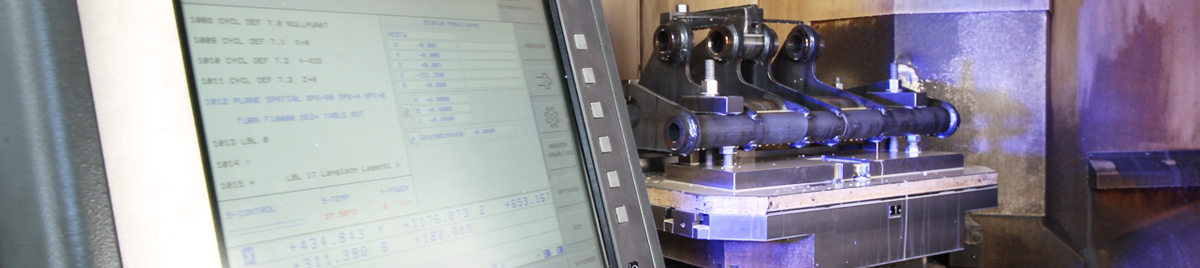

Machining is the starting point for most production parts. The machinery facility consists exclusively of CNC-controlled machines which are operated by our qualified personnel in up to three shifts. Cutting is also carried out by CNC and NC-controlled automatic sawing machines.

Parts up to a length of 3000mm can be processed in the turning shop. Machines with portal loaders and even bar lathes with Y-axes complement our 100% in-house production. We identified the current trend of equipping hydraulic cylinders with a displacement measuring system years ago and perform the required machining steps using deep-hole boring machines.

In the milling centre, parts up to a unit weight of 1.5t can be machined on 3-, 4- and 5-axis machining facilities. The majority of the machines are equipped with pallet changers enabling low-cost machining thanks to intelligent machine loading.

All production parts pass through our automatic washing machines several times during the manufacturing process to remove any residues. Complex parts, such as valve bodies, are deburred and cleaned by hand and then transported to the assembly department.